The history of Leborgne

Leborgne iron know-how ?

Leborgne is an ancestral expertise in the forging, design and manufacture of hand tools.

A link between history and the future that anchors it, much more strongly than Made in France, in Made in Savoie, in the heart of the Massif de Belledone where the company was born and remains established.

It was in the 11th century that the Leborgne family revolutionised tools and the daily lives of their users. Drawing on the expertise of the Carthusian monks, who had specialised in pruning tools since the 11th century.

Discover our story

Leborgne It was with this in mind that Pospère Leborgne developed a metallurgy activity in 1829. Émile Leborgne, his descendant, instilled in the company values that are still relevant today: agility, adaptability and quality of manufactured products.

For him, innovation and people were the key: the beginnings of Leborgne's user-centred design!

He described his vocation as ‘creating adapted tools to better help people to create’.

Technical revolution after revolution, Leborgne wants to remain the ‘yellow and green’ reference for bricklayers, carpenters, gardeners, woodcutters and other professionals and enthusiasts, thanks to what makes up its DNA: design.

Almost 2 centuries of history

The story of a region.

Leborgne was born in Savoie

In 1829, the Leborgne family, partly from France and partly from Savoie, ( oh yes, don’t forget the Savoie region only became French in 1860), developed activity in metal working in the heart of a territory where forging in smithies had already been present for centuries. In fact in the Valley of the Bens (in the Belledonne mountain range) the Chartreuse monks forged swords, axes and other cutting weapons which formed the equipment for knights leaving for the Crusades, at the very end of the 11 century.

The 19th century saw the expansion of the railway, shipbuilding, the opening of the Panama Canal by Ferdinand de Lesseps as well as other works as the colonial Empire continued its expansion. Emile Leborgne, who was an experienced entrepreneur, specialised his forge in the production of hand tools that were original, adaptable and of high quality for a demanding clientele.

Creating a centre for steel working with a world-wide perspective

To meet the increasing flow of orders, Emile Leborgne encouraged the opening of other autonomous workshops for makers of edge tools in the region. Thousands of shovels, the famous « Allevardes »were exported to Egypt. In the Tonkin Leborgne’s rice field spades were used and in Algeria Léborgne’s pick axes were used.

The product range was considerably enlarged. And it needed to be, most of these new products were adapted or even improved according to the geological and geographic conditions of the countries or regions where they would be used.

After the Great War, adapting to the fall in prices

The company, which was now in the hands of engineer Yves Lozach’meur, Jeanne Leborgne’s husband, realised that it must invest in the latest mechanical means available in the years between the two World Wars, in order to produce greater quantities and higher quality.

Quality, attention to needs and innovation. After the Second World War, Yves and Michel Lozach’meur made investments, the site was electrified and the company succeeded in expanding it’s market again both in France and in bordering countries.

La relève est assurée par Denis et François Lozac’hmeur

In the 1980’s Denis and François took over from their father Yvon Lozach’meur. The world had changed considerably with the arrival of the leisure era, new technologies, competition on a world-wide scale.. Leborgne had shown its capacity for adaptability time and again and now responded to the challenge with its chosen arms at the ready: quality, attention to needs and innovation.

What’s more, the clients are aware of this : in an IPSOS survey carried out in 2010 91% put quality first when choosing Leborgne products.

Today 2 sites.. . more Savoyard than ever !

Expanding rapidly, Leborgne opened a second production site in 2000 in La Rochette, 3 kilometres from the historic site in Arvillard where the forge is situated.

In La Rochette Leborgne has set up a workshop for fitting handles and fixing labels on tools as well as a distribution centre for shipping throughout the country and abroad.

This site also houses the sales division of the company. Here the main issues are merchandising, consumer information and promotional dynamism…

Nowadays

In 2007, the last owners Denis and François Lozac'hmeur sold the company to the Finnish group Fiskars. Fiskars is going to develop the plant, introduce major innovations and support sales growth until 2019.

At that point, a new Rhône-Alpes family business, Sextant, takes over Fiskars' assets and recreates the Leborgne company.

Leborgne, the inventor of ‘yellow handles’

The Leborgne credo is to offer the most complete range of handles possible, with strength, safety and comfort to meet every need.

A look back at a revolution...

- In 1988, with the Nova® bi-material handles, Leborgne became the first manufacturer to offer very high-strength fibreglass tool handles. This was simply to replace handles that had previously only been made of wood, and to offer users greater safety.

- 10 years later came the Novagrip® and then Novamax® handles, equipped with a larger fibreglass core and made of three different materials. Ultra-resistant handles for ever greater ergonomics, design and maximum safety.

- In 2003, Compositube® handles in glass fibre-reinforced polyamide, with their hollow handle (no core), combine lightness, high strength, rot-proofing and comfort in the hand.

Useful innovation from the functional point of view with the Batipro® range

- The Batipro hammer (1999) with magnet and lateral striking surfaces, for use in confined spaces

- The club hammer (2001) with its 2 upper edges at a sharp angle for scraping

- The heel bar (2001) fitted with an aluminium tube and a steel head, weighing in at only 4.5kilos instead of the traditional 12 kilos (for forged steel)

- The rake with reinforced lateral tines (2009) with a round socket sleeve for greater bending resistance and a rule on the top for levelling.

The Nanovib® anti-vibration revolution

At the time of the pension reform in November 2010, the subject of reducing arduous work was at the heart of the news. Leborgne, with its visionary R&D thinking on the subject, is revolutionising the hand tool market with the Nanovib® anti-vibration hammer.

Not only was the product a success, but it also marked a genuine change in the way people relate to tools, which are now (also) judged on their ability to guarantee user safety and protect their health.

Momentum is building. Since 2010, the Nanovib® range has gone from strength to strength !

The natural garden with NaturOvert

Still at the end of the 2000s, it was time for the Grenelle Environment Forum and the beginnings of ‘zero-phyto’.

Leborgne's philosophy: why use chemicals when you can achieve the same results with mechanical hand tools?

The NaturOvert® range was created in 2009, with the hoe and scraper of the same name.

For this range, Leborgne's R&D department adopted a new method: feeltesting.

Different prototypes were tested by gardeners from the City of Lyon. Their ‘feeltesting’ feedback is used to select the most effective blade and launch it into production.

How can we protect the environment with simple mechanical tools ?

- With the Biogrif® and Rotogrif®, the gardener decompacts the soil without turning it over, thus preserving the micro-organisms living in the soil.

- The NaturOvert range can be used to prepare the soil for planting, weed naturally, aerate the soil or work it without having to bend down.

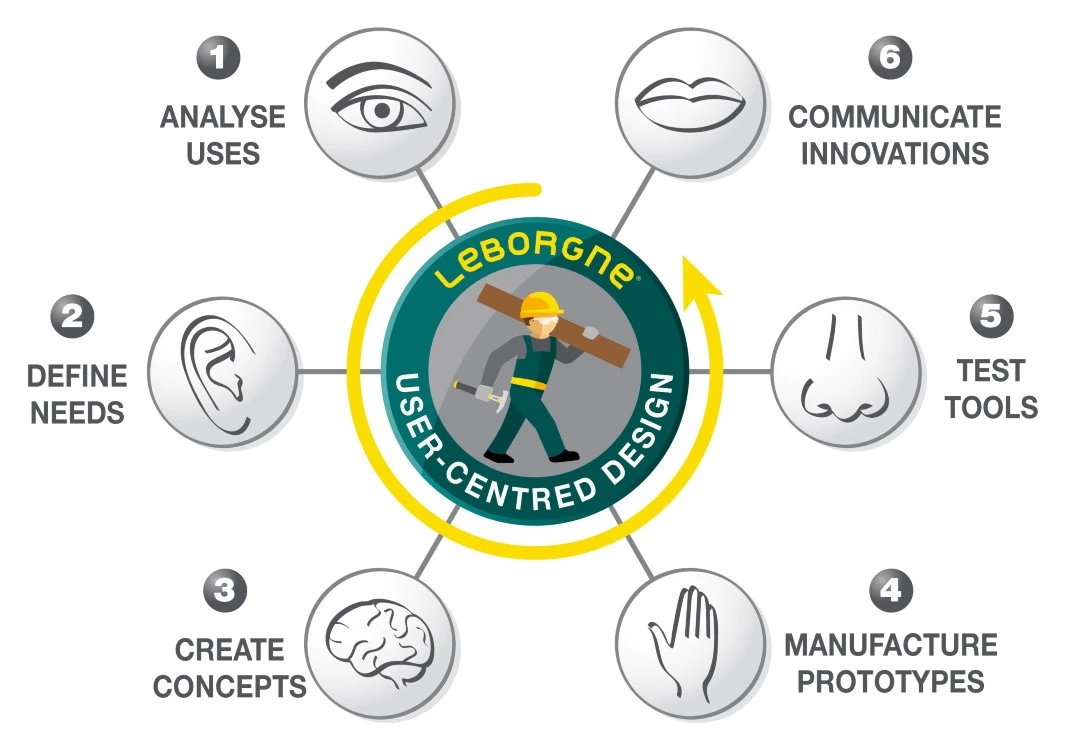

Design at the heart of Leborgne innovation

Innovation centred on the needs of users: it has been Leborgne's strength and DNA since 1829. The aim has always been to innovate in order to improve functionality, comfort or health and safety, in order to adapt Leborgne products to your needs.

The Leborgne method: starting with the customer's need before it reachs your hands

Leborgne's R&D department meets with users to observe and identify their problems of use and ergonomics.

Prototypes are then created, tested by users and modified until an optimum level of satisfaction is reached.

Once this level has been reached, the industrialisation of the product can begin.

Leborgne's approach was recognised by the European Design Managment Awards in 2012.

‘Leborgne [is] yellow and green, sunshine and nature’

Leborgne products retain a unique visual code that is recognisable and synonymous with ‘beautiful tools’ for our customers.

The brand values its colours and their symbolism, as well as the typical lines of Leborgne tools: rounded shapes for the gripping part of the tool for greater ergonomics and comfort; and marked lines for the working part of the tool, underlining a great intransigence on quality.

Leborgne design has been rewarded by prestigious prizes

- Plumb line Metäspro : Gold medal in Batimat Design 2009

- In 2011 Nanovib claw hammer honoured by 3 awards : Red Dot Design, Star of the Observateur du Design and the Gold medal of Batimat Design

- Bolt-cutter nominated in the category of innovation by Observateur du Design

- 90cm anti-vibration handle : star of Observateur du Design 2015

- Pincers : star of Observateur du Design 2016

- Scraper : star of Observateur du Design 2017

- Digging spade : star of Observateur du Design 2018

- Ergonomic handle for gardening tools : star of Observateur du Design 2019

- Pole shaft : Expoprotection 2022 Trophy

- Oiler with diffuser : 'Janus de l'Industrie' 2023 label of excellence