Safety at Leborgne

The Leborgne hammer, the tool, symbol of safety for the brand

Remove the « risk of.. » is one of the first demands of Leborgne. It is the quality of the forged tool, and not the absence of danger from it, which is the first guarantee of safety given by Leborgne from the very beginning of the company in 1829.

From the start the quality of Leborgne tools has contributed to the brand’s reputation especially among construction workers.

From

the wooden handle to the composite handle, for increased safety

From the wooden handle to the composite handle, for increased safety

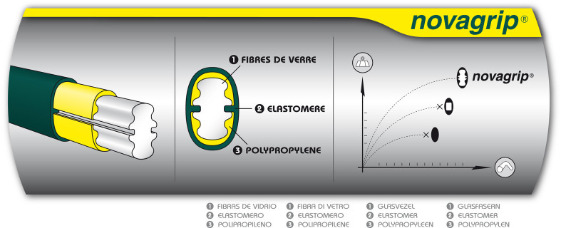

In 1988 the « Nova » handle, the first composite handle on the market gave unrivalled breaking resistance and surpassed the wooden handle. This was a real breakthrough at the time and reinforced the image for quality of the brand.

Safety

and new functions go hand in hand

Safety and new functions go hand in hand

At Leborgne the R&D is always supported by a thorough knowledge in the field. How and in what conditions do construction workers use the tools ? What are their constraints and their demands ?

In 1998 thanks to this willingness for observation and attention to needs, Leborgne added an extra function to its famous hammer :a flat lateral surface which enables the user to hit with the side of the hammer. The workers become more effective and it is easier to use in confined spaces.

A third type of material is at the origin of the BatiPro range. By adding an elastomeric grip to the fibreglass handle, the Leborgne hammer becomes even safer. This technical development is at the origin of Leborgne’s BatiPro range. And the hammer is its bestseller !

Nanovib range :the professional solution to reduce physical strain at work

Nanovib range :the professional solution to reduce physical strain at work

After focusing first of all on preventing the risks of accidents, Leborgne has added another string to its bow by seeking to protect the user’s health. There are new tools to combat occupational illnesses and in particular RSI (first cause of occupational illness in the construction industry).

Objective: combat physical strain at work

.Working in partnership with the INRS, a long study was undertaken on the hammer handle to reduce the transmission of vibrations to the forearm. Following numerous tests on specific machines, the Nanovib range (go to « Nanovib range ») was launched in 2011.

For professionals, it is a breakthrough ! When it was presented at the 2011 Batimat trade fair, the Nanovib hammer transformed the attitude to tools. This was no longer just a hammer and Leborgne was the first company in the marker to square the circle: quality, safety, easy use, safety.

It was an instant success and since then the Nanovib range has expanded with numerous other items.

Leborgne is calling for the creation of an anti-vibration standard for hammering.

To find out more about safety regulations in the construction industry ( go to « regulations »).

Leborgne’s

most famous innovations

Leborgne’s most famous innovations

Heel bar reduced to a third of its original weight, making handling easier

The hammer scraper is ideal for removing concrete laitance after striking formwork, replaces the use of the miner’s bar

The insulated miner’s bar removes the risk of electrocution (<1000v) when an electric cable is accidently struck during road work

The prop key eliminates all noise when tightening or loosening prop bolts

The rack gear bolt-cutter reduces physical effort by 30% during cutting

The angle of the Nanovib hammer pouch prevents the hammer from falling when the user crouches down

The telescopic scraper with a length of 2 to 3.5m means users do have to hold arms above the rotator cuff while working

The long reach panel remover with its 1.85m handle enables site workers to strike the ply board panels whilst standing on the ground without the use of mobile access platforms and therefore prevents the risk of accidents.

Our professional partners in anticipating risks and reducing physical strain on work sites

Our professional partners in anticipating risks and reducing physical strain on work sites

In order to meet the requirements of companies in the construction industry who are trying to find solutions to reduce the physical strain endured by their employees, Leborgne has formed partnerships with experts in prevention : OPPBTP, IRIS-ST (prevention section of CAPEB), safety managers of major construction companies and builders. The new Nanovib tool range is the result of this process.

Impartial and objective results

On 24th April 2012 Leborgne signed a partnership agreement with CAPEB and IRIS-ST to test and offer innovative tools for risk prevention to companies. This three party agreement guarantees impartial and objective results.

In-house, a dedicated team in Savoie in France and in Billnäs in Finland (the Test-Lab of Fiskars Group which Leborgne belongs to) (Go to « history of a territory ») specifies the rigorous technical demands and checks chemical and mechanical characteristics as well as the vibration levels of our tools.

Leborgne partner of CAPEB since 2012

Different partners to respond to various issues

With CARSAT, Leborgne combats RSI in general to improve health for construction workers

With OPPBTP Leborgne observes safety issues related to jobs in the building industry and in public works

With CAPEB, CNATP, FFB and EGF-BTP Leborgne focuses on the emerging needs met by craftsmen, SME, general and major building companies and public works companies.

Leborgne is also an active member in all discussion forums in order to participate in exchanges and remain at the heart of the expectations of the profession : CETIM (technical centre for mechanical industry) SIO (union for tooling industry) UNM( union for mechanical standardisation) Afnor, chamber of commerce and industry Unibal ( National union for DIY industries) FEDIYMA, ( similar to Unibal but at a international level) CNDB (National centre for wood), SYNAMAP ( National union for the active market participants in prevention and protection)…