How to prevent the risk of noise from repeated impacts on the work site?

Striking on prop bolts with a hammer : the second biggest cause of noise on a work site.

A very familiar sound on work sites is the sound of a hammer brutally hitting prop bolts to loosen or tighten them, when installing or dismantling tower access platforms or scaffolding. Noise pollution which can be harmful to the hearing of the worker who is hammering as well as those in the vicinity, all the more so, when it repeated.

Following exposure to intense noise of this sort,the worker may suffer from temporary ringing in the ears or buzzing which is called tinnitus and also a loss of hearing acuteness.

Where there is no further exposure to noise, this strain on hearing will disappear in time. However, if there is repeated exposure to intense noise levels, the health risk becomes serious. Indeed it can cause irremedial damage to the inner ear, leading to permenant deafness.

It is also worth remembering that noise increases the risk of work accidents, for several reasons :

Noise covers the sound of alarm signals

It makes verbal communication more difficult

It is distracting.

How to eliminate noise on a work site?

The company head is required to measure noise levels in order to identify any noise which may exceed the regulation threshold values. And if necessary he/she must take the appropriate measures to preserve workers’ health regarding hearing.

There are two methods for measuring noise pollution:

Sonometer measures taken near the worker during significant work periods

Exposure measures : continual measure of noise level during the working day, by using a exposure meter worn by the worker

Depending on the results, individual or collective protections may be provided. Alternative option: as they are used every day, tools are a significant means of improving working conditions.

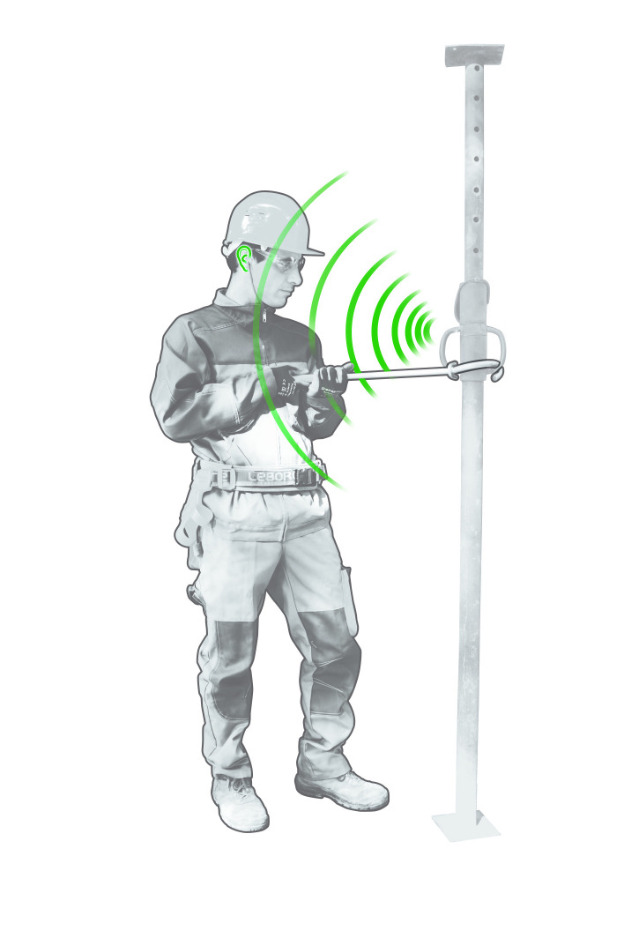

Leborgne Nanovib prop key totally eliminates the noise of impact

The least harmful noise is the noise you do not make. With this in mind, Leborgne produced a prop key in partnership with safety managers from large construction companies. Aim: to make the work of tightening and loosening bolts easier with an innovative tool to replace the use of a hammer.

As the gesture used is no longer the same, noise pollution caused by hammering on bolts is purely and simply eliminated.

Other advantages of the nanovib prop key

Using the Leborgne nanovib prop key instead of a hammer also helps to reduce the risk of MSD in the forearm as a result of vibrations caused by hammering on the prop bolt.

For added comfort, the nanovib prop key has rubber coating for perfect grip.

Where to find the nanovib prop key?

Find out about useful innovation at Leborgne

See other files

- How to prevent the risk of backache due to moving heavy loads on a construction site ?

- How to prevent the risk relating to mechanical vibrations on a work site ?

- How to prevent tiring positions on a work site using formed concrete construction ?

- How to prevent the risk of repetitive work on a site ?

- On a construction site how to prevent the risk of electrocution ?