On a construction site how to prevent the risk of electrocution ?

The risk of electrocution, a major issue for safety in the construction industry

With omnipresent electric networks the professionals in the construction industry and in public works are exposed to risks whatever type of work they do.

Even if the number of accidents relating to electricity has decreased significantly in France, there are hundreds of serious cases every year. The risk of fatal acccidents is considerably higher than the risk of work accidents in all professional domains.

According to a study in 2010 the National board of health insurance (Caisse National de l’assurance maladie) for salaried employees on a construction site :

- 0.7% of accidents involving electricity are fatal compared to 0.08% for other risks

- 10.5% of accidents involving electricity are serious (permenant disability) compared to 6% for other risks.

How to eliminate teh risk from electricity on a construction site?

The company which is responsible for the work must consult the centralized system (“Guichet unique”) to obtain the list of users to consult and send them the DICT (declaration of intention of starting work) in order to obtain information relating to the localisation of underground networks and recommendations aiming to prevent damage to networks and the risks which agents may be exposed to.

The Guichet Unique is updated by users who must add any new underground network created. The site manager must consult the Guicher Unique to fill in the Dossier for company consultation.

The responsibility for risk involving electricity is therefore shared between the site manager, the users and the companies responsible for the work.

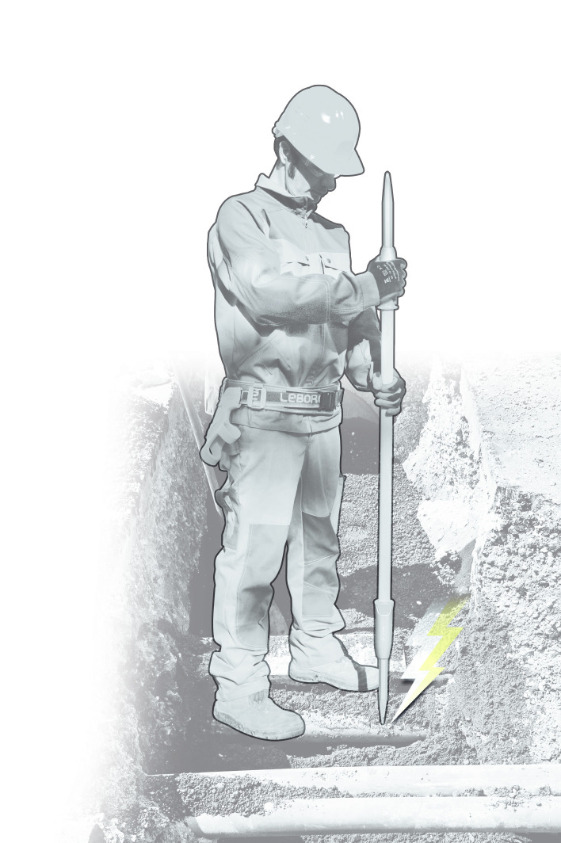

Nanovib insulated miner’s bar to avoid the risk of electrocution

Following an accident on a worksite of a major public works company which led to the electrocution, which fortunately was not fatal, of one of their workers, the Safety and Quality manager – aware of the active role of Leborgne in the prevention of physical strain and work accidents – contacted the R&D department at Leborgne ask them to create an insulated miner’s bar.

Designed for levrage, moving loads, lifting stones, digging trenches …in ground where live electric cables may be present , the Leborgne nanovib insulated miner’s bar can eliminate all risk of electrocution up to 1000V for alternating current and 1500V for direct current (in compliance with BS8020).

Other advantages of nanovib insulated miner’s bar

It weighs 20% less than a traditional all steel miner’s bar which makes handling easier. So it prevents risks relating to carrying loads.

Its robustness comes from the body (central part) made of 100% fiberglass which guarantees levrage capacity up to 1.5 tonne and from the forged steel working parts (pointed end for digging and peen end for levrage).

Its ergonomics. The central part of the nanovib insulated miner’s bar made of fiberglass with oblong section gives comfortable grip.

Where to find the nanovib insulated miner’s bar?

Find out about useful innovation at Leborgne

See other files

- How to prevent the risk of backache due to moving heavy loads on a construction site ?

- How to prevent the risk relating to mechanical vibrations on a work site ?

- How to prevent tiring positions on a work site using formed concrete construction ?

- How to prevent the risk of repetitive work on a site ?

- How to prevent the risk of noise from repeated impacts on the work site ?